Trigger a constant,

Reciprocate a pulse,

Pew-pause-pew-pause-pew

Kept getting ads for an electric, automatic water gun a while back on Temu/Aliexpress. For $10, it was hard to turn down if only for the lulz. Also kept getting yelled at by my dentist and hygienist for not flossing properly, so I got a cheap waterpick off of Amazon as well. I just took both apart, since they're pretty much the same, right?

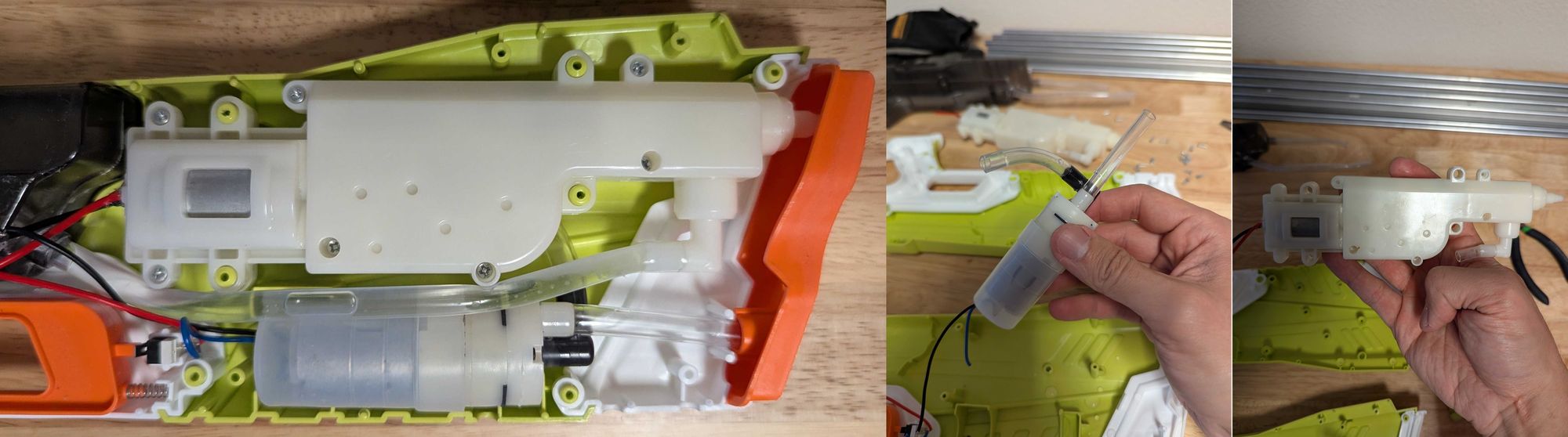

Aliexpress Watergun

Surprisingly low-tech with wiring jankier than what I could've ever dreamed. Pulling the trigger like normal shoots out pulses of water, and pushing it the opposite direction allows the gun to siphone water through the barrel area and refill the internal tank. Electronics-wise, there's just a microswitch at either end of the sliding trigger, each one driving a separate motor subsystem: a pump that pulls in the water, and a reciprocating piston similar to what you'd find in airsoft guns to squirt water. No boards or any other circuitry, not even for charging. You actually need to unscrew/unclip an outer covering, detach the battery, and manually charge it via USB.

With switches, multiple motors, and a single battery, you'd expect at least a few split or spliced wires, and there were, but there was nary a piece of heat shrink or drop of solder in sight. The wires are just stripped and wrapped a couple of times around each other. This is some next-fucking-level tomfoolery. Or cost-saving genius. I still need some time to process.

Away from the exposed wiring, the tubing and sealing look pretty good. The entirety of the pump looked to be enclosed, and though the motor body of the output mechanism is exposed (presumably for cooling), the rest appear well protected against ingress with adhesives, seals, and grease. As long as only the business end of the water gun is submerged, I doubt water would get to anything it shouldn't, but it's still a bit unnerving that something battery powered plays so fast and loose with the internals. On the outside, there's a flimsy film and some minor grease covering each of the exposed screws, which I suppose is better than nothing.

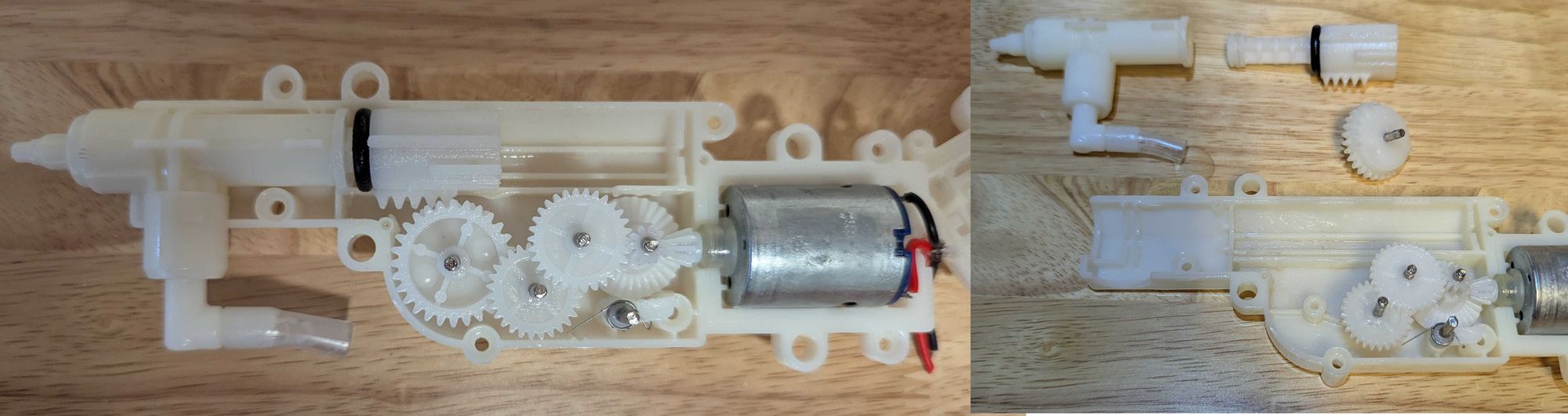

Looking at the firing mechanism, I couldn't quite figure out how, if at all, the output line was primed, and if there were any other air holes elsewhere to help with the overall circulation. There's a heavy duty compression spring missing in the pictures above, as the gear train draws back the plunger until the partially-geared final spur gear runs out of travel. That action draws in water from the (presumably non-empty) reservoir. The spring should release energy much faster than the geared motor, which can reload the fluid much more slowly.

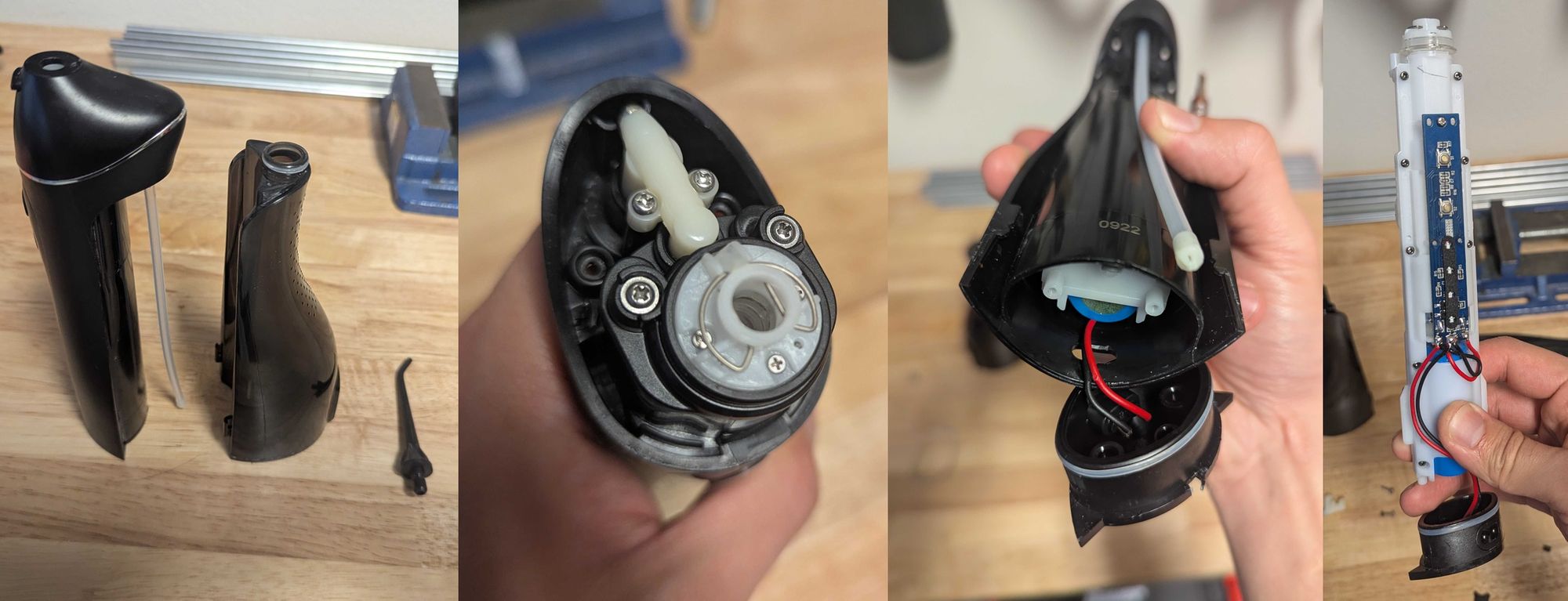

Waterpick

Compared to the discount electric water gun, the home waterpick is a lot of the same: a motorized pump draws water out of a refillable reservoir and then forces it through a much smaller orifice at a regular rate. Unsurprisingly, the assembly is much cleaner, miniaturized, and it doesn't elicit concern when I shove it in my mouth. No metal fasteners or anything else that could corrode are exposed on the outside in any way, seals and gaskets are found in any of the mechanical interfaces/separations, and the core fluid connections are tightened down via fasteners, not just reliant on press-fits.

The main outer body is a singular piece that appears to have been ultrasonic welded together out of smaller pieces. The internals sort of slide in and get sandwiched by the bottom base and top cap. There's a large number and selection of itty bitty fasteners. I'm not sure if this suggests a large number of 3rd party vendors for each of the subcomponents or poor DFM planning or something else. I've wondered before why manufacturers still go with a large number of small fasteners for mechanisms that aren't meant to ever be serviced, and now I wonder if it's because mechanical fasteners are still most reliable from an assembly workflow perspective. I assume finagling with adhesives, especially when dispensed via manual, handheld tooling, just invites more mess and inconsistency.

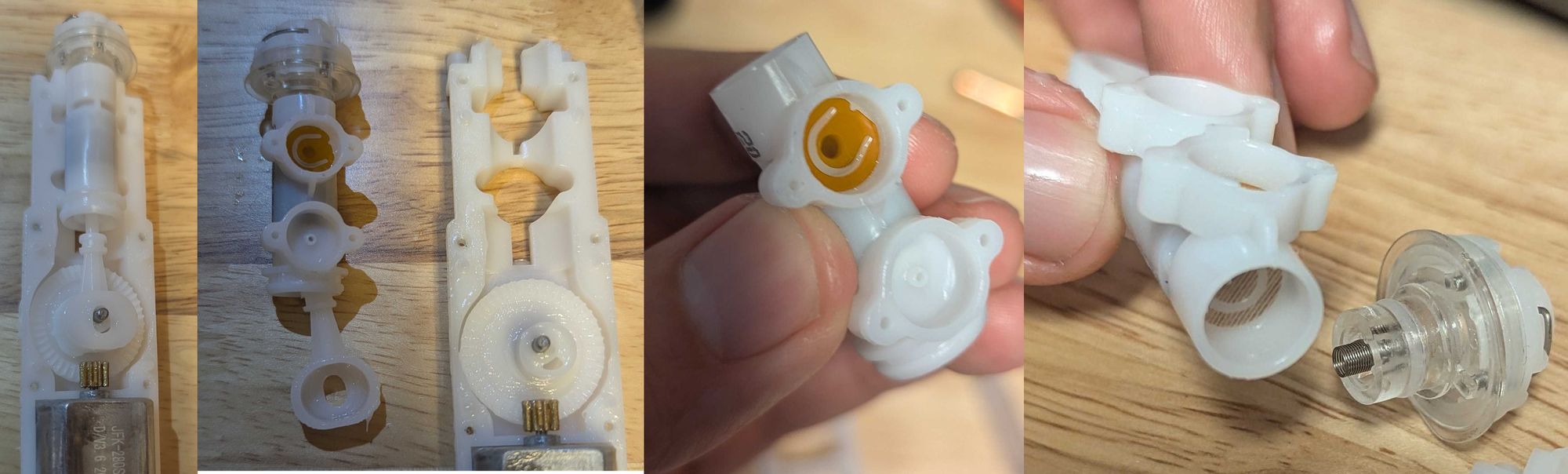

I found the little clip that holds onto the interchangeable nozzles to be pretty cool. Each nozzle has a little radial notch near the base, which gets clamped by a compliance c-clamp like wire around the output head at the top of the waterpick. The outer tool-release button wedges the metal wire open when depressed. I suppose it also helps that most nozzles are mostly press-fit onto the waterpick anyway even if the wire wasn't there.

Unlike the water gun, this waterpick was blessed with an actual electronics board with BMS to charge the battery and a way to toggle between different pulsing speeds. The soldering between the board and the motor terminals is part of the board's final attachment to the main assembly body.

The pump is a re-packaged/re-configured diaphragm pump that draws from the main tube and simply spurts the water out the nozzle while minimizing the overall packaging constraints. A bevel gear runs an eccentric cam driving the primary piston which runs a series of two one-way diaphragm valves to direct water in the appropriate direction. The piston itself interfaces with a thin stainless steel tube insert within the plastic housing. There's a tiny compression spring at the output that I assume is meant to preload the last diaphragm flap shut when not in use and avoid leaks, though I'm not totally sure.

The part geometries, especially the diaphragm housing, are non-trivial, though I wonder if other low-cost waterpicks (I didn't exactly buy a brand-name implement) share a common internal body structure, much like how basic 12V diaphragm pumps are all essentially identical. I wouldn't know without taking apart more of these from other vendors, but I'm curious just how else designers manage to keep the overall form factor minimal in reformatting the standard pump.