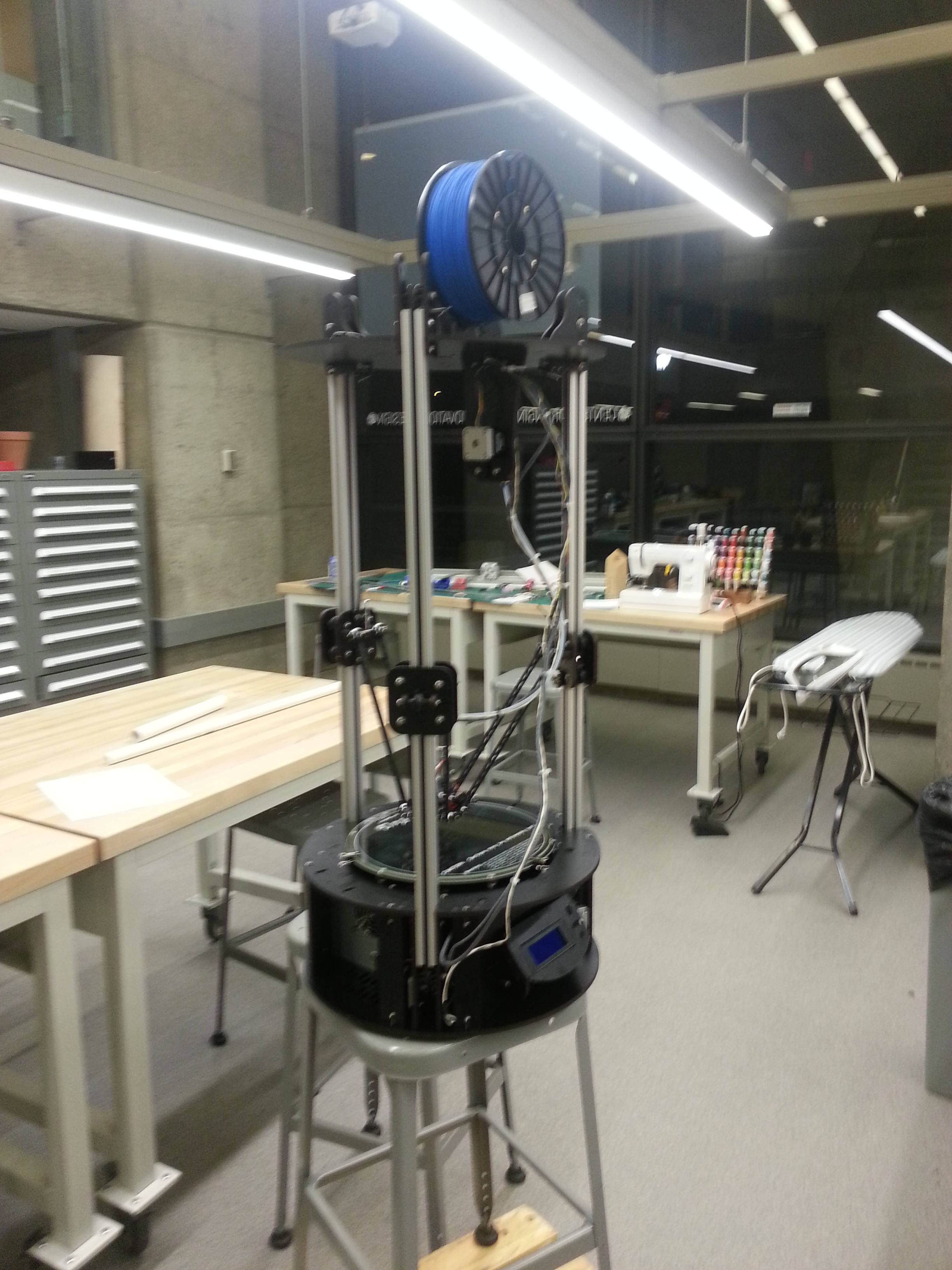

Behold the delta,

Three long arms to rule them all,

atypically fast

I've been meaning to document my experiences with the Rostock MAX 3D printer for a while now, especially since I've had the machine for a little over 7 months now, and the printer's manufacturer has already released a V2. Looking back, I guess I had some pretty non-mainstream reasons for getting a 3D printer. I already have access to quite a few on campus, including two in our lab and a few more available through Yale's student design space. I had made a quick customization app as part of a hackathon early last year (I sort of think 3D printing is pretty useless without the proper consumer-based UI for customization, but that's a long-winded rambling for another time), but I didn't (and still don't) have any plans for making plastic trinkets, functional or decorative. I mainly got a printer to see whether I could upgrade a DIY kit to perform as well as or better than our industrial FDM machines (the Stratasys uPrint and Fortus 250mc). My goals up until now have been:

- Learn more about g-code and path planning w/ respect to 3D printers

- Implement all existing hacks to maximize accuracy/precision of the printer

- Build heated enclosure

- Build tool-changer or implement multiple extruders

- Build another 3D printer from scratch

For household consumers, I've always found 3D printing to be interesting in that it's so closely tied to the DIY, maker community, since the technology itself is so relatively new. Industrial applications aside, desktop FDM printers built by hobbyists can often produce parts of similar quality to industrial offerings from companies like 3D Systems or Stratasys, so much so that patents and IP are (imo) major stumbling blocks to innovation, and a company like Makerbot could go from a darling of the Reprap community to hated sellout in less than a year. It's pretty neat that tinkerers working out of garages and basements (and university labs late at night) can be on the bleeding edge of desktop printer development, as everything is still relatively new.

A printer by itself is pretty straightforward: extrude melted plastic at a certain rate while moving along some path in some coordinated way. Basically, we're just copying your standard CNC mill but without worrying (too much) about loads on the tooling. The most standard machines move the bed in Y and the extruder in X and Z, which simplifies the building of the frame and allows for the use of weaker stepper motors, since you minimize the number of stacked movement axes riding on top of each other. Some other variations move the bed in Z and the extruder in X and Y.

The Rostock MAX, as a delta machine, works differently. Delta machines are parallel mechanisms, where the control inputs are connected to the end effector more directly and often in symmetric ways. In contrast, the more standard serial mechanisms may have one or more motion stages mounted onto another motion stage (ie. the X axis moves on the stage that moves in Z on the original Reprap machine). While the mapping from input to output may be easier on a serial mechanism, movement errors will propagate and stack, whereas errors on a Delta machine can be mitigated by being "averaged" across the various (in this case, 3) connections. Since the motion stages/carriages are mounted independently, the entire system can move a lot faster, and it's easier to ensure a rigid end effector.

But let's be honest, the most important reason to use a parallel manipulator for your 3D printer's movement is because it's fun to watch =)

I was certainly concerned about a lot of potential issues prior to deciding on a delta design:

- There are more connections that may interfere with the printer's operation, so debugging would be a problem.

- Print resolution is inconsistent across the build plate, since the mapping from input (vertical motion of the carriages) to output (XYZ motion of the end effector) is nonlinear. In contrast, with either leadscrew or belt-driven stages, the serial cartesian printers have linear mappings from input to output.

- A lot of additional vertical real-estate is needed for a Delta printer. While it's easy to extend the vertical workspace, a significant portion of the machine is reserved just for accommodating the vertical motion of the Delta machine arms.

- To minimize weight, I'd need a bowden-setup instead of direct extrusion, and so proper retraction to reduce oozing may be more difficult to calibrate.

Of course, the coolness factor eventually won out over my concerns, and you can see my progress in modifying my printer below:

Coming from a more cartesian-CNC background and having actually taken a course where we built a lathe from scratch, I have to say that I'm still having trouble getting a grasp on fine-tuning the machine. It just hasn't been very intuitive in figuring out what may be causing certain errors. I'll probably write more in the future about my observations just so I can do a proper review of the design considerations I think should be optimized in building affordable printers. That said, I still absolutely think this machine was the right one to get given the available selections at the time (end of 2013) and the fact that my primary goal was to make printer modifications. Just in this past year, it feels as though the support community (1,2) for delta printers has grown by leaps and bounds, and that's certainly helped me a great deal as well.